Recycling technology

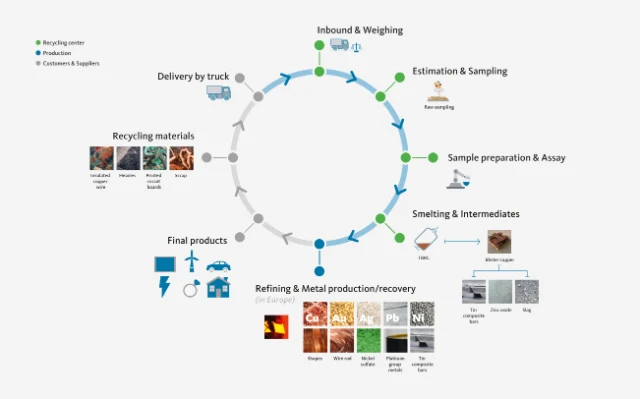

Smelting, refining, transforming: These keywords describe the various metallurgical processes we use at Aurubis to extract valuable metals and other basic materials from copper concentrates, scrap, complex recycling materials, and intermediate products. At Aurubis Richmond, we will process about 180,000 t of complex recycling materials annually and produce 70,000 t of blister copper.

We are the industry leader in complex, multimetal raw material processing and high metal recovery rates. Each Aurubis site and every team leverages its expertise and know-how here: Our smelters in Beerse, Berango, Hamburg, Lünen, Olen, Pirdop and Richmond are each specialized for different input materials and produce various metals ranging from copper to tin. And the teams at our sites in Hamburg, Olen, Avellino, Emmerich, Pori and Stolberg process copper cathodes into rod and shapes, and flat rolled products.

The material is then shredded and sampled to determine its metallurgical composition. A representative sample is taken, processed, and then analyzed in the laboratory.

The sampled material is then prepared for use in the furnace. It is first blended into a furnace mixture and loaded into the Material Handling System (MHS). Slag-forming agents, such as sand, are also added to the MHS. The MHS transports the various mixtures and slag-forming agents via a conveyor belt system into bunkers, where they are stored for direct use in the top blown rotary converters. To charge the TBRC, the bunkers are partially emptied and the material is conveyed into the TBRC.

The TBRCs are the metallurgical core of the new facility. This is where electronic waste is recycled through complex metallurgical processes. The melting and converting steps produce blister copper and slag. The slag generated during the melting process is fed into the slag holding furnace. There, the remaining copper is separated and returned to the TBRC. The low-copper slag is then granulated and discharged as grains smaller than a postage stamp.

The slag produced during the converting process has a high tin content. For further processing, it is fed into the lead-tin furnace and combined with additives such as iron. This allows the tin to be concentrated and, after several more processing steps, recovered as a lead-tin alloy in block form.

The blister copper produced in the TBRC is transported in ladles to the casting plant using the overhead crane. The liquid blister copper is carefully poured from the ladle into small molds. These molds are arranged on a conveyor belt and give the blister bars their distinctive shape. They are then cooled, stacked, bundled and packaged for shipment.

Environmental protection is a fundamental part of the Aurubis strategy, which is why the exhaust gas system is especially important. Process extraction, divided into two phases — primary and secondary extraction — captures the gases generated during the complex metallurgical processes in the furnaces. These gases are then transported via pipelines to the gas cleaning system.

The gas cleaning system removes pollutants such as furans and dioxins as well as metals. In the afterburning chamber, the exhaust gas is first oxidized, then cooled, filtered and washed. Gas cleaning is essential for meeting emission standards. The zinc oxide collected in the filter as a by-product is an important contribution to zinc recycling, upholding the highest environmental standards in the process.